Working For You

Allen knows that it’s not just about an advanced facility, it’s about the valued personnel that works within it. Our production specialists and technicians are highly trained in the art of assembling and testing complex assemblies for aircraft applications. The procedures we perform are well documented and reviewed for improvement on a regular basis. Our specialists work closely with our engineering and quality divisions to assure the highest standards are met. We coordinate our workflow in teams, with lean manufacturing principles set in place, allowing us to maintain the highest level of efficiency and deliver our products on time.

In the assembly process, we utilize a wide array of fixtures and tools to accommodate assembly methods to fulfill the design and performance parameters of the products we supply. In addition to traditional mechanical assembly methods, we perform soldering, brazing, and epoxy potting of electronic components.

Testing Tools

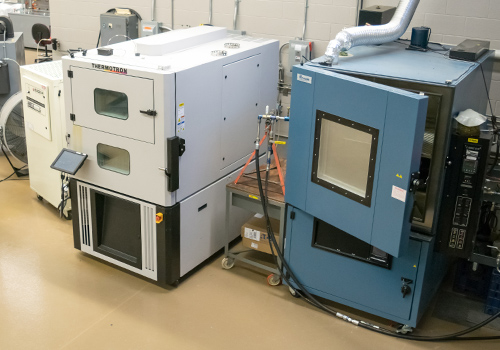

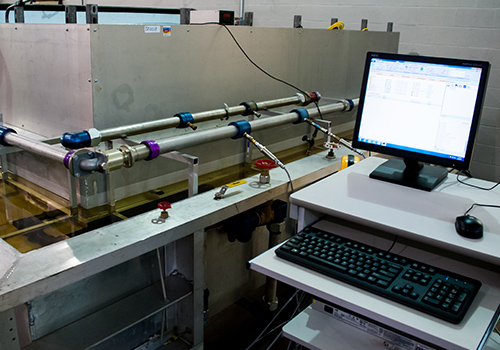

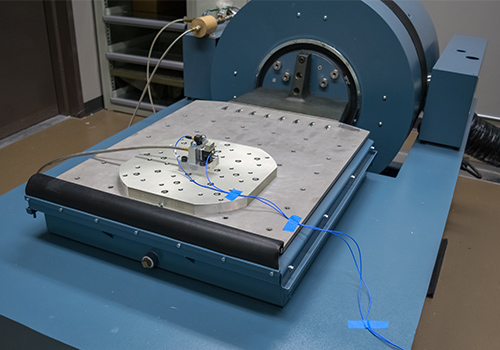

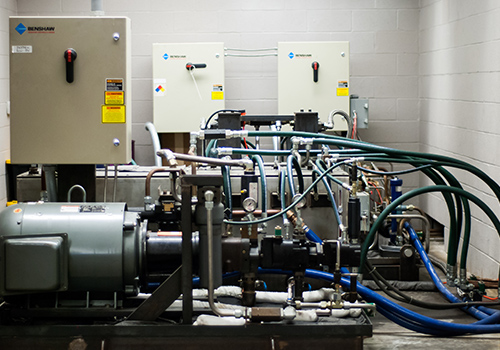

Allen maintains a wide range of test facilities to verify the performance of our products. Fluid power characteristics are verified for both flow and static conditions in fuel, air, water, hydraulic oil and engine oil within a wide range of flow and pressures, under a variety of environmental and operating conditions.

Special qualification equipment includes vibration tables, altitude chambers, environmental chambers, temperature shock chambers, and multiple rigs that simulate continuous cycling.