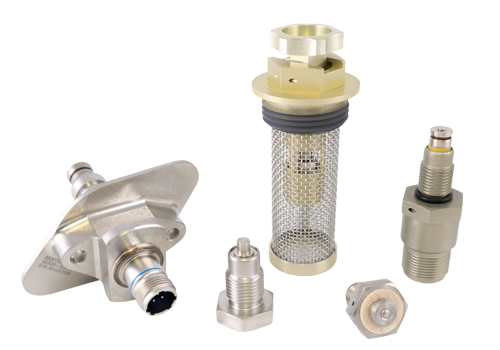

Allen offers multiple types of sensor components that help foresee system malfunctions. Thorough research has shown that metal particles in the lubrication system of an aircraft engine or hydraulic system may be an indication of wear. The chip detectors that we designed are used to monitor these systems and provide early warning of impending failure, allowing maintenance to be performed on a timely basis. The detector houses magnets that are incorporated into an electric circuit. These magnetic lines of force attract ferrous particles that begin to collect. The collection continues until the insulated air gap between the magnets (two magnet configuration) or between the magnet and housing (one magnet configuration) is bridged, effectively closing the circuit. The result is an electronic signal for remote indication.

Chip Detectors

Chip detectors may be positioned in the application with a self-closing valve/adapter through either a bayonet or threaded interface. As the chip detector is disengaged from the valve, the valve closes, minimizing any fluid loss from the system.

Self Closing Valves

Self-closing valves offer a practical, economical solution to fluid loss problems in applications requiring more frequent inspection of magnetic plugs or chip detectors. Available in threaded or bayonet designs, the valves close down automatically as the magnetic plug or chip detector is removed. This eliminates the loss of expensive lubricants and reduces the need to clean up after inspection. As a result, inspection is faster and more convenient for maintenance personnel.

Both types of self-closing valves offer maximum exposure of the magnet to the flow of lubricant or hydraulic fluid. The wide-open design is essential to proper functioning. If the free flow is restricted, ferrous chips and particles are less likely to come in contact with the magnet.

Self-closing valves are sealed with “O” rings, providing a positive seal under the low-pressure condition generally associated with their application. The “O” rings seal the valve when the plug is in position and when it is removed for inspection.

Strainers

Allen Aircraft supplies a full range of screens with or without chip detectors. The screens are provided in either aluminum or stainless steel material and are sintered, resistance welded, or brazed. The screens in a forced flow oil lubrication systems come in various screen openings. Debris particles that are larger than the screen openings are retained by the screen.

When a screen assembly is equipped with an integral electronic chip detector, the debris is attracted to the chip detector and electronically shows an indication. Many screen assemblies with integral chip detectors are also provided with a self-closing valve. The self-closing valve permits quick removal of the chip detector for inspection without the need to drain the oil system.

Oil Level Indicators

Allen produces a full line of oil level indicators for monitoring fluid levels in aircraft engine and power system applications. Models are available which provide both a visual as well as remote indication via an electronic signal. Multiple level indication sensors are available.

Visual indicators use optically ground lenses to enhance level indication. Remote indicators provide electronic signals based on float position which can be interpreted to provide the pilot or maintenance personnel with accurate fluid level condition.

Oil Filler Caps

Allen Aircraft oil filler caps are easy to install and remove and provide an oil tight seal around filling ports for tanks and reservoirs. Most designs include a lanyard to prevent the cap from dropping during removal. Our designs also include optional screen assemblies to prevent the ingress of potentially damaging foreign material.

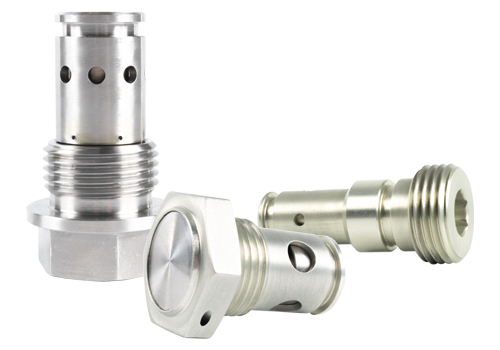

Cartridge Valves

Cartridge style check valves are commonly used in high-pressure systems to isolate hydraulic circuits or to provide a by-pass feature around restrictions. Allen Aircraft valves are durable and offer low leakage throughout the life of the part. Typical design pressures range from 5 psi (0.34 bar) to 3100 psi (214 bar).