Extensive Aerospace Testing Lab

Allen Aircraft, Inc. maintains a wide range of testing facilities and special qualification equipment to verify environmental, structural, and functional performance of aircraft products and material.

We work closely with our customers to assure the highest standards are met. Contract with Allen to ensure your materials and products are safe, reliable, and compliant.

Connect with Allen Aircraft testing engineers.

Data Acquisition

- 8 Channels per Unit – Stackable

- Sample Rates – 0.1 hz to 2400 hz

- Strain gauge Half or full bridge

- Current-fed piezoelectric transducers

- Piezoresistive full bridge

- Thermocouples (Types J, K, T)

- Ohmic resistor

- Potentiometric transducers

- Inductive half or full bridge, LVDT

- Voltage (±100 mV, ±10 V, ±60V)

- Standardized current (0 – 20 Amp)

- Rotary encoder, frequency measurements

Fluids

- Aviation Fuels

- Dow Frost

- Engine Lube Oil (7808, 23699)

- Red Oil (5606, 83282)

- Skydrol (500B, LD4)

- Stoddard Solvent

- Water

Testing Chambers

Shock Chambers

- 24″W x 23″D x 14″H

- 100 lbs capability on basket

- Hot Zone: 71°F to 411°F

- Cold Zone: -100ºF to 356°F

Altitude Chamber

- 38″W x 38″D x 38″H

- D0-160 Icing: -90°F to 350°F

- Humidity: 10% to 95%

- Altitude: up to 100,000ft

- 10.8°F / Min Ramp Rate

Environmental Chambers

- 38″W x 38″D x 38″H

- -90°F to 350°F

- Humidity: 10% to 95%

- 18°F / Min Ramp Rate

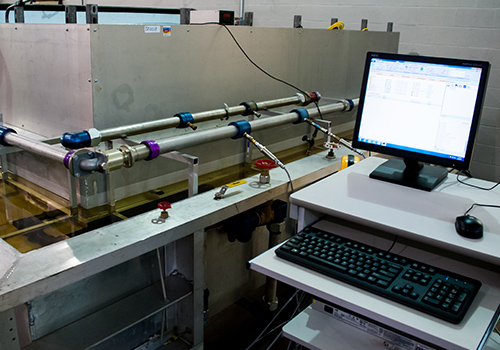

Fluid & Vibration Testing

Fuel Testing

- 60 gpm up to 175 psi

- 300 gpm up to 100 psi

-40°F to 180°F

Oil Testing

- Max: 40 gpm up to 5000 psi

- 12,000 psi Static pressure

Air Testing

- 440 CFM @ 125 psi

- 90 CFM @ 300 psi

- 17.5 CFM @ 5000 psi

Vibration Capabilities

- Sine: Up to 8,000 lbs Peak

- Random: 8,000 lbs RMS

- Shock: 19,000 lbs Peak

- Frequency: 3 Hz – 2,000 Hz

- Axis: Three with slip table

- Mode: Sine, Random, SOR, ROR, Classic Shock, Trac

- Data: 8 – 12 Channels per Table

- 100g Max Control

- 500g Max Response